When Fluids Meet Nanomaterials: Establishing a Fluid-Assisted Nanomanufacturing

Drs. Bo Li and Qianhong Wu

As the United States aims to revive its manufacturing industry, two Villanova University Mechanical Engineering professors are committed to establishing a field of advanced manufacturing with highly interdisciplinary features. Specifically, Drs. Bo Li and Qianhong Wu are pursuing exciting new developments in the nanomanufacturing of flexible electronics, which requires collaborators in nanomaterials, mechanics, electronics and manufacturing to build circuits and devices on flexible polymer substrates. These devices have applications in health monitoring, drug delivery, energy storage and personal entertainment, and thus have the potential to reshape the human lifestyle.

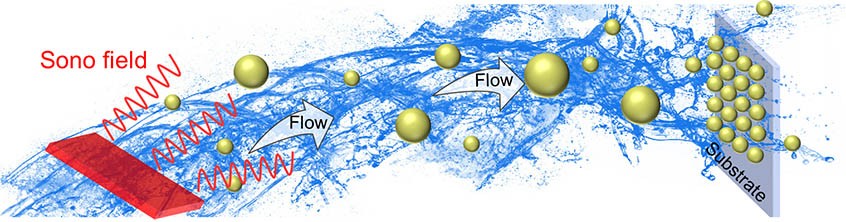

As the forefront of advanced manufacturing develops further, new challenges emerge. Given their small size and outstanding functionalities, nanomaterials have been enthusiastically embraced in flexible electronic manufacturing and functional coatings; however, their inherent size variation presents a significant challenge for repeatable and reliable device manufacturing. Traditionally, a separate nanomaterial sorting process is required, which is not only costly but also slows down the manufacturing process. With a new, three-year, $499,957 grant from the National Science Foundation (NSF) for "Sorting and Assembly of Nanomaterials on Polymer Substrates Using Fluidic and Weak Ultrasound Fields for Fabrication of Flexible Electronic Devices,” Drs. Li and Wu will combine their individual areas of expertise in nanomaterials and manufacturing (Li), and fluid mechanics modeling and experimentation (Wu) to address nanomanufacturing limitations.

The intersection of fluids and nanomaterials was discovered two years ago when Dr. Li first invited Dr. Wu to his lab. He explained to his colleague: “Currently, developing nanomanufacturing is like cooking. You throw different ingredients into the pot and see how it comes out. It’s all experimental.” In looking at the challenges from his perspective, Dr. Wu detected what he called “exciting fluid mechanics problems in these cooking processes,” caused by fluids meeting nanomaterials. This meeting of completely different disciplines led to close collaboration between the two research groups and their ambitious initiative to establish a new field of fluid-assisted manufacturing.

With this NSF grant, these professors are taking a unique approach to developing a highly efficient sorting-assembly manufacturing process that selectively assembles nanomaterials with similar sizes into nanostructures. Their novel method combines a fluidic control mechanism—flow chambers that are primarily used in cellular biomechanics research—in the nanomanufacturing process. “No one has thought about using a flow chamber system to grow nanomaterials,” says Dr. Wu. “We use analytical models that are typically applied in drug delivery research to precisely describe the transport, deposition and assembly of nanoparticles in the fluidic-assisted systems. The goal is to uncover the underlying physics of the nanomanufacturing process.” Dr. Li adds: “The introduction of weak sonication will significantly promote the productivity of the manufacturing process. It also raises interesting scientific questions about how these two fields interact and create synergy to achieve better sorting and assembly of nanomaterials.”

There is a long list of potential benefits and applications for fluid-assisted nanomanufacturing. Dr. Li cites, for example, a new generation “Fitbit” that conforms or adheres to human skin for health monitoring and medical treatment. “A flexible substrate enables conformal adhesion to surfaces (like skin) with complicated geometries,” he explains. In addition, nanomaterials with different functionalities can be integrated for tracking health conditions such as pulse and glucose level, and others can be applied as agents to treat the diseases.

In another example, as functional coatings nanomaterials might be applied to a car windshield for anti-fogging and anti-icing such that no wiper is needed. They can be applied to house siding to prevent mold growth and keep the surface clean for years. In industry, these functional coatings can be used to protect industrial products of all sizes from hand tools to giant cruise ships.

Dr. Li emphasizes: “The meeting of fluids and nanomaterials creates unlimited opportunities in advanced manufacturing. As we advance knowledge in nanomaterials assembly and discover the key fundamental mechanisms of nanomanufacturing, we will have more choices of materials and functionalities, better device repeatability, significantly enhanced efficiency and affordable flexible electronics.”

In addition to their NSF grant, Drs. Li and Wu were recently awarded a Manufacturing PA grant, in partnership with ExOne, to develop improved 3D printing processes for porous microparticles. “At this point, we’re reading each other's minds and finishing each other’s sentences,” Dr. Wu says only half-jokingly when discussing his highly successful collaboration with Dr. Li. Along with their recent funding, their partnership has yielded two published journal papers with several more pending proposals and research papers. Both professors are fully committed to securing funding and exploring and establishing this new field of fluid-assisted nanomanufacturing.