The ME Makerspace: Facility for Innovation and Student Advancement

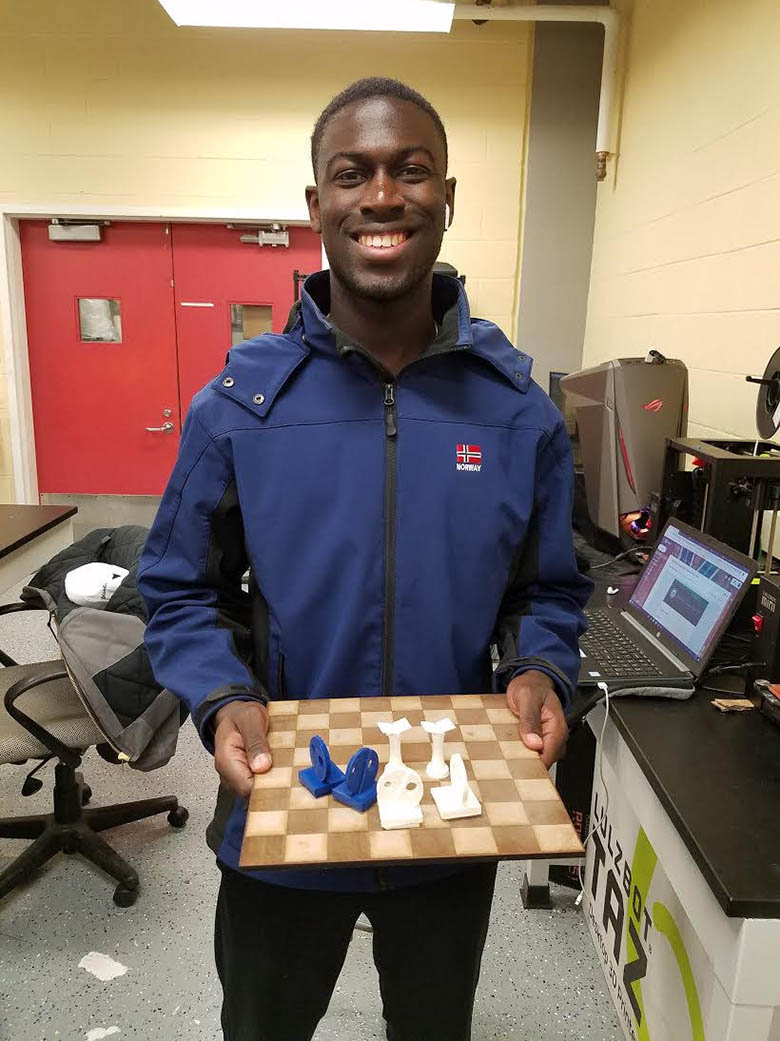

Junior Mechanical Engineering major Richard Annan created his 3-D printed chessboard in the ME makerspace.

In 2018, the College of Engineering established a new Mechanical Engineering makerspace with funds donated by alumna Coleen Burke-Finney '90 ME and her husband Michael Finney. We asked Dr. Patrick Kirby ’06 ME, a visiting professor in the College of Engineering’s Mechanical Engineering Department, about this special place for students to complete schoolwork or express their creativity through personal projects.

What is the ME Makerspace?

A makerspace can take many forms and be used for a variety of purposes. Overall, the form of a makerspace will be dictated by the community that is involved with its use. As the name implies, a makerspace is a place where things get made. Beyond this, the ME Makerspace is a location that is available:

- To pursue individual initiatives

- Gather for collaboration and learning opportunities

- Use for coursework

- Relax

The makerspace can be used for class and research projects as well, but the main purpose of the room is to facilitate student-to-student interaction and the development of their ideas. Therefore, much of the learning that students complete in the makerspace comes from other more experienced makers and the students’ own passions.

What are students learning?

Students learn how to use machines for the purpose of rapid prototyping and fabrication. Some of the equipment found in the ME Makerspace includes:

- Table space for collaborative and individual work

- 3-D printers

- A laser cutter

- A drill press

- Soldering tools

- Basic hand tools

Beyond equipment training, the makerspace is a place for ideas and knowledge to be shared. This shared knowledge includes information on the design process and innovation.

Who’s involved in the Makerspace and what is being built?

The student projects are very diverse, including ornaments, customized kitchen dishes, guitars, carabiners, and many other creations. Transferring pictures onto wood or other media also appears to be very popular. A variety of parts and linkages for robotic-associated projects have also been fabricated within the Makerspace. Students of all levels are heavily involved with the ME Makerspace, along with some staff and faculty. Day to day operations are overseen by Preston Whitman, who is a graduate student within the Mechanical Engineering