ME Makerspace: Spawning Creativity, Innovation and Racecars

by Griffin Davis ’22 EE

3D printed dashboard

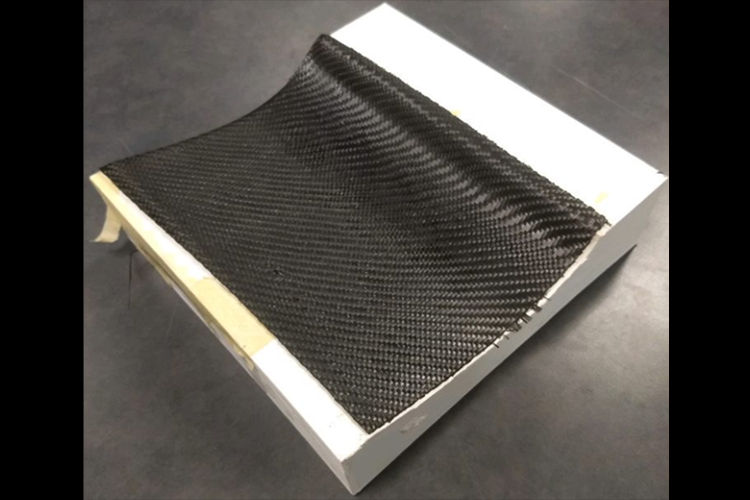

3D printed small scale wing to practice carbon fiber layup techniques

Dashboard base laser cut acrylic with 3D printed hand grips

Last year, an article was written about the Mechanical Engineering Makerspace in which Visiting Professor Dr. Patrick Kirby stated, “The form of a makerspace will be dictated by the community that is involved with its use.” This year, Villanova’s Formula SAE team, NovaRacing, has become an engaged member of that community. Formula SAE competitions challenge teams of university undergraduate and graduate students to conceive, design, fabricate, develop and compete with other schools’ formula-style vehicles. Villanova’s team has found that ME Makerspace is an ideal setting in which to accomplish much of the early stages of the process.

ME Makerspace supervisor and Formula SAE Public Relations Lead and Safety & Interface Lead Samantha “Sam” Sandler ME ’20 explains how the facility serves the team’s needs:

What is the Makerspace used for?

With regard to Formula SAE, both the 3D printers and laser cutters are used significantly in prototyping. Specifically within the system of driver controls, many components must be prototyped in order to gather feedback from the drivers as it relates to comfort, visibility and optimizing driver performance. In other systems of the car, the designs are evaluated on a scale that is more quantifiable and can be analyzed through calculations and virtual simulations.

Manufacturing is a critical aspect of all systems on the Formula SAE team and the Makerspace is utilized as an opportunity to prototype designs before final fabrication, practice with different manufacturing techniques, and generate small-scale products for additional testing (such aerodynamics being tested in a wind tunnel).

What equipment is being prototyped this year?

Most recently, the 3D printer was used to prototype a dashboard and hand grips for the steering wheel, and the laser cutter was used to form the foundation of the steering wheel from acrylic. The benefit of 3D printing the dashboard is that the electrical lead can place the components in the dash to ensure that the tolerances are correct and that no other components interfere with visibility or accessibility.

The Aerodynamics team recently utilized the 3D printers in order to test different carbon fiber mold- making techniques on small scale wing profiles.

What are NovaRacing’s goals?

Team Captain Christopher Auslander CpE ’21 spoke to us earlier in the semester about NovaRacing’s goals this year: “Our main goal for this year is to improve our car's performance by adding a new aerodynamic package. This will help with our overall handling, control and speed around corners. The improvements that we make to the vehicle this year will be extremely beneficial to our current team and future teams.”