Research

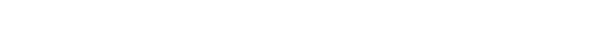

The cross-section view of an ordered nanoparticle thin film (the inset is the top view).

1. Synthesis and Characterization of Nanoparticle Thin Film (NTF)

Nanoparticle thin films (NTFs), i.e. thin films composed of nanoparticles, exhibit synergistic properties, making them useful for numerous advanced applications. However, many NTFs have a poor resistance to mechanical loading and abrasion, presenting a major bottleneck to their widespread use and commercialization. We are working on providing techniques to greatly increase the mechanical durability of NTFs. We have demonstrated that atomic layer deposition (ALD) at a relatively low temperature can drastically improve the mechanical durability of nanoparticle films on organic and inorganic substrates. This research is a collaborative project with Dr. Daeyeon Lee at University of Pennsylvania.

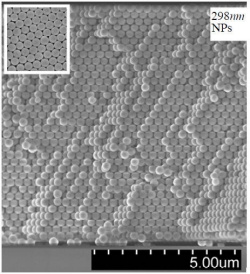

The TEM image of Herringbone graphite nanofiber Structure

2. Synthesis and Characterization of Energy Storage Materials with Nanostructures

Many sustainable energy systems feature cycles of increased and decreased energy production and thus need the ability to store energy for use during times of decreased supply. Phase change materials (PCMs) store energy through the utilization of the latent heat of fusion and have been implemented successfully at the small scale. However, the low thermal diffusivity of most standard PCMs prevents effective heat absorption in larger systems. A graphite nanofiber based (GNF) nano-enhanced PCM has been developed and shows both improved thermal conductivity and specific heat in the bulk material, leading to greater energy storage effectiveness. However, this work has also identified a thermal resistance which occurs at the interface of the nano-enhanced PCM and the heated base caused by the motion of the nanofibers away from the surface in the near-wall region after multiple thermal cycles. The research objective is to develop a reliable and durable energy storage material with an enhanced near-wall energy transfer rate through establishing a well-controlled functionalized carbon-nanofiber network embedded in a PCM. This research is a collaborative project with Dr. Aaron Wemhoff at Villanova, which is supported by National Science Foundation (NSF).

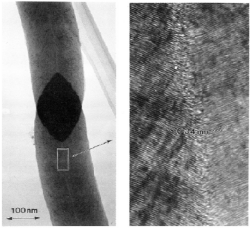

The topographical image of a GaN nanowire after a nanoindentation.

3. Characterization of Individual Nanomaterials (Nanowires, Nanotubes, NanoShells, & Nanoparticles)

Nanowires, nanotubes, and nanoparticles have a wide range of potential applications, such as chemical and optical sensors, resonators and force sensors, high-resolution scanning probe microscope (SPM) tips, and reinforcements for nanocomposites. On the other hand, because of their extremely small dimensions, it has been very challenging to characterize and manipulate these nanomaterials, and the study is the central topic of nanotechnology. We are working on providing techniques to accurately and quickly characterize nanomaterials, so that we are able to evaluate different nanomaterials for designing high performance nano-systems.

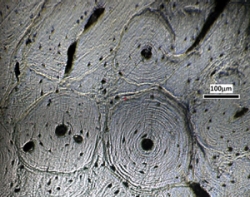

The micrograph of a bovine bone cross-section

4. Nanomechanical Characterization and Modeling of Hard Tissues

Biomaterials, e.g., bone and dentin, are natural multi-scale hierarchical organic nanocomposites, and after millions or even billions of years of evolution, their properties are optimized. Through studying the behavior of biomaterials at different hierarchical length-scale level, my group hopes to decode the design and optimization principles by Mother Nature. Then, the decoded principles can guide us to design materials and systems with optimized performance. In fact, nanoindentation is one of very few techniques which can be used to characterize biomaterials in their native environments, e.g., being immersed in liquid. Moreover, the fully understanding of the properties of bone at the nanoscales will provide important new knowledge for the development of target-specific therapeutic treatments on altering the bone microstructure to prevent bone fracture, which would have great impact on improving human health.

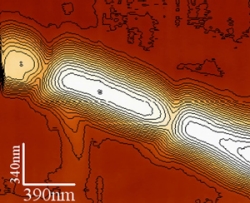

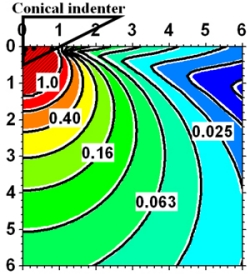

Elastoplastic indentation stress field (von Mises stress/ yield strength)

5. Fundamentals of Small Scale Mechanical Characterization

AFM and nanoindentation are two amazing tools, among only a few techniques, being able to test, manipulate, and visualize materials at small scales. These two techniques can provide the applied force and the corresponding deformation, which are important to determine mechanical response. The sensitivity of AFM is generally much higher, while nanoindentation can give more quantitative information and allow for more direct control and measurement. Although the measurements through the two techniques can provide the information for many properties, only the methodology for determining hardness and modulus are well known. Therefore, it is critical to de-convolute the measurements to determine other properties at small scales. For example, we have provided an analytical solution for the stress field around a permanent indent/contact. This solution is important for understanding the contact/impact response of the material at multi-scales and potentially useful for various fields, for example, bearing, metal forming, electrical contact, tribology (friction and wear), nano-/micro-electromechanical systems, contact-induced fracture and fatigue, and nanoimprint.