Mechanical Engineering Capstone Design Courses Better Reflect Industry Trends

For the 2018/19 academic year, the Department of Mechanical Engineering updated the capstone design course to better reflect industry trends. The course continues to be project based over two semesters, but it is now strictly focused on design – build – test projects that enable students to be hands-on, as well as gain prototyping and troubleshooting experience.

The course consists of two integrated components:

(i) The classroom component has been expanded to provide students with the tools to not only design but also implement a complete engineering project. This includes lectures on teamwork, project management, design process, industrial safety and project commissioning.

(ii) The project component includes developing a precise scope of work, finalizing a detailed design, building a prototype, testing and troubleshooting.

The course mimics the practice of an engineering consulting firm. The student team interacts directly with their customer to develop a precise scope of work and validate the design work as it progresses to ensure it satisfies their requirements. Each student team is assigned a faculty advisor who provides guidance and coaching to the team and ensures students remain on track to meet the academic requirements of the course. Faculty advisors are the equivalent of a department manager in the fictional engineering firm.

Renewed effort has also been put forth to partner on industry-sponsored design projects. This allows student teams to gain first-hand exposure to design problems faced by industry, develop professional skills and interact with experienced professionals. Over the past three academic years, industry sponsored projects have comprised approximately two-thirds of all projects, with repeat sponsorships from companies such as Lockheed Martin, Material Sciences LLC, FMC Corporation, L3Harris and Armstrong World Industries. These partners benefit from having some back-burner projects executed with a fresh perspective, all while identifying a talent pipeline for their recruiting efforts.

In addition to industry assignments, other projects continue to be offered to provide opportunities to meet the wide interests of Villanova students, such as through the Villanova Engineering Service Learning (VESL) program and from faculty researchers. For example, a recent service project is the 6” PVC Pipe Connection Method that was developed for a gravity fed water system in Cañazas, Panama. The community obtained 12km of pipe (in 3m lengths) to expand their water system, but they had no way to connect the pipes together. The capstone team spent several weeks discussing the objectives with the stakeholders and developed a detailed scope around performance specifications (water pressure, repeatability, cost) and design constraints (weight/size for transportability, power requirements). The team brainstormed multiple concepts, developed objective criteria to select the best overall concept, and then completed the detailed design of their heated expander that creates bell-shaped ends on each pipe length for assembly. In the spring semester, they built a prototype and performed some preliminary testing in the shop before traveling to Panama for field testing over spring break. Upon their return, the team had to troubleshoot issues with alignment and failure of the glued joints. After some design improvements, the team completed their functional demonstration by successfully pressure testing 20 pipe joints. In early June 2019, the unit was returned to Panama and put into production for the benefit of the community.

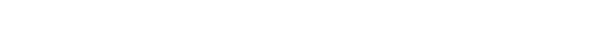

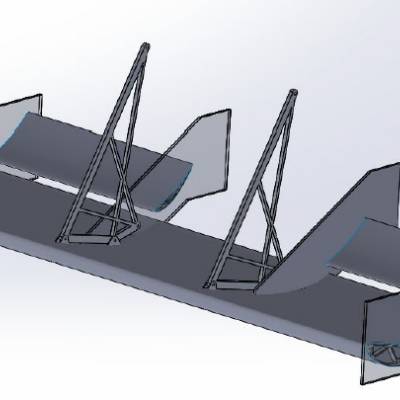

The capstone course also supports Villanova student groups such as Nova Racing, and it was the catalyst for starting teams participating in the MATE (underwater robotics) and Design-Build-Fly (aircraft) competitions.

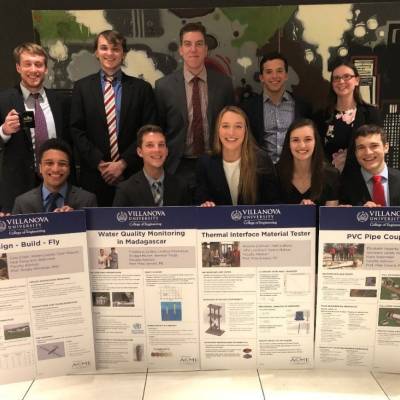

Our new approach has allowed Villanova students to be recognized by the ASME Philadelphia chapter, resulting in eight project teams each earning a grant in the last two years.

These course updates were implemented in the on-going effort to foster a dynamic learning environment for students and to better bridge the classroom to the modern engineering workplace.

We extend special thanks to our 2019 and 2020 sponsors:

- Advanced Cooling Technologies

- Armstrong World Industries

- C2K Innovations LLC

- DePuy Synthes

- FMC

- L3Harris

- Lockheed Martin Space

- Material Sciences LLC

- Materials Design & Research, Inc.

- Piasecki Aircraft

- Prime Technologies

Watch this short video to learn more about Capstone sponsorship: https://youtu.be/Z8OzJnXKXCY. We welcome new sponsors.